Briquette Machine Structure

Briquette Machine Structure

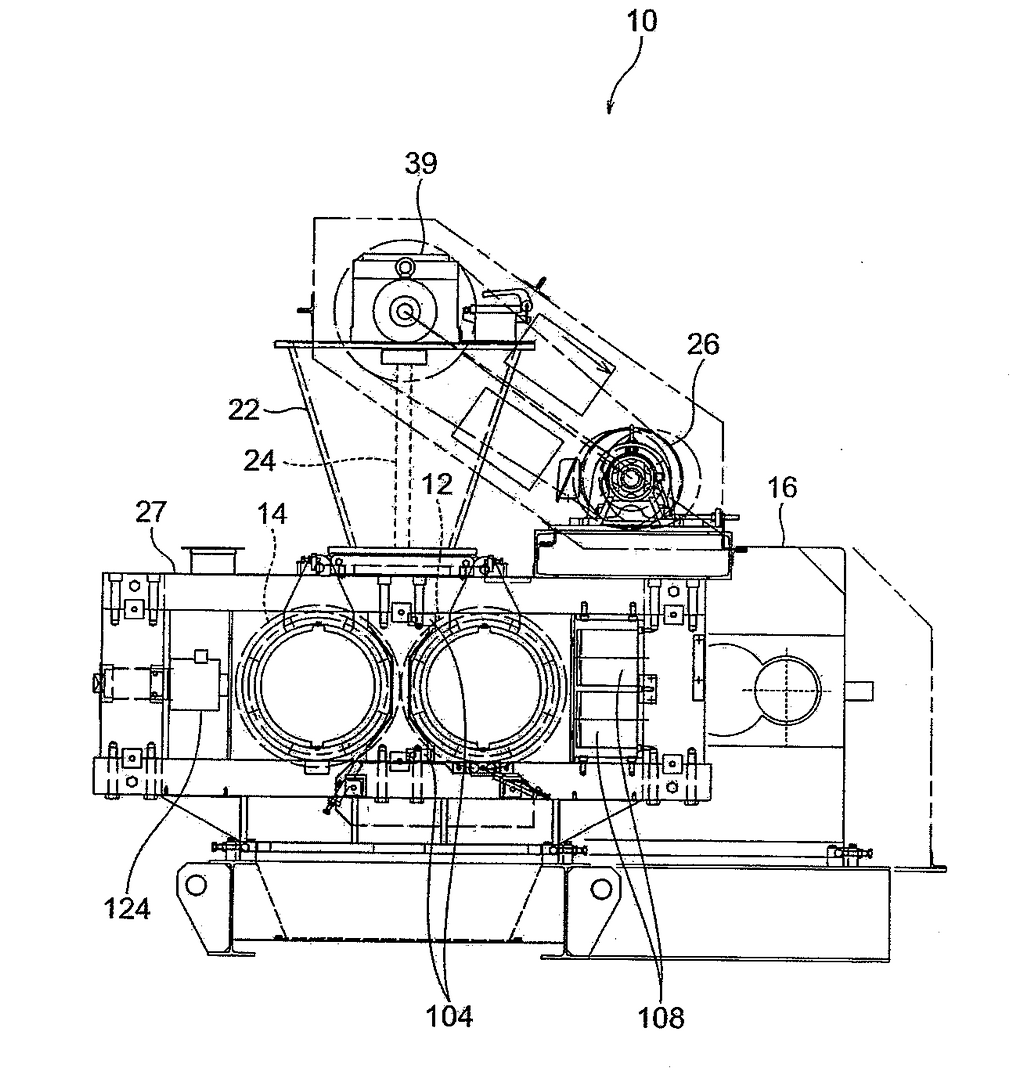

1. The briquette machine comprising:

a first roll and a second roll that each are ring-shaped, having the axis of rotation of the first roll and that of the second roll being disposed parallel to each other and each roll having pockets on its outer surface whereby raw material is compressed between the pockets of the first roll and those of the second roll;

a driving unit that produces a driving force for rotation;

a first coupling member that conveys the driving force for rotation of the driving unit to the first roll;

a rotating member on the roll-side that rotates with the second roll as one body;

a rotating member on the side of the driving unit that is rotated by the driving unit;

a mechanism for adjusting the position of the rotating member on the roll-side along the direction of the rotation of the rotating member on the roll-side relative to the rotating member on the side of the driving unit; and

a second coupling member that conveys the driving force for rotation of the driving unit to the second roll.

2. The briquette machine according to claim 1, wherein the mechanism for adjusting the position that is disposed at the position that is to the outer side in the radial direction as seen from the center of the rotating member on the side of the driving unit, the mechanism for adjusting the position comprising:

a nut disposed so that the axis of the nut is laid parallel to the tangential direction or the radial direction of the rotating member on the side of the driving unit;

a bolt that is screwed into the nut; and

a pressed portion that is formed on the rotating member on the roll-side where the tip of the bolt contacts the rotating member on the roll-side wherein the pressing force is exerted by the tip of the bolt in the tangential direction or the radial direction of the rotating member on the roll-side as the bolt is screwed into the nut.

The briquette machine according to any one of claims 1-3, wherein the briquette machine comprises:

a bearing unit on the fixed side that supports an axis member that is disposed on either of the first roll or second roll and that can rotate with the roll as one body;

a bearing unit on the movable side that supports an axis member that is disposed on the other of the first and second rolls and that can rotate with the other roll as one body, the bearing unit on the movable side being movable in the direction of the radii of the first and second rolls wherein it can contact, or can retract from, the bearing unit on the fixed side; a spacer adjusting the gap, which spacer is disposed between the bearing unit on the fixed side and the bearing unit on the movable side and which is to form a gap between the first and second rolls;

an oil hydraulic cylinder that is disposed on the side opposite the bearing unit on the fixed side with the bearing unit on the movable side laid in between, the hydraulic cylinder being disposed in such a way that its axis is positioned in the direction of the line that is in common with the radius of the first roll and the radius of the second roll, each of the radii being perpendicular to the rotating axis of the first roll and that of the second roll, and the hydraulic cylinder having a cylinder rod that has a member for adjusting the position in the axis-direction on one end;

a pressure-detecting device that is disposed between the other end of the cylinder rod and the bearing unit on the movable side and that detects the pressure between the other end of the cylinder rod and the bearing unit on the movable side;

a hopper disposed above the first roll and the second roll;

a feeder screw disposed within the hopper, which screw pushes the raw material within the hopper down and between the first and the second rolls by the screw being rotated,

a variable-speed control motor that drives the feeder screw, and

a control unit that controls the variable-speed control motor in such a way that the rotation of the feeder screw is decreased or increased corresponding to the increase or decrease of the pressure that is detected by the pressure-detector.

the first roll and the second roll, one of which is fixed in the direction of its radius and the other of which can contact, and retract from, the one of the first roll and the second roll in the direction of its radius;

a hydraulic cylinder that applies the pressure on the other of the first roll and the second roll if the force is exerted on the other of the first roll and the second roll in such a way that the one of the first roll and the second roll retracts from the other of the first roll and the second roll;

a hopper that is disposed above the first roll and the second roll;

a feeder screw disposed within the hopper, which feeder screw pushes the raw material within the hopper down and between the first roll and the second roll by the screw being rotated;

a variable-speed control motor that rotates the feeder screw;

a detector that detects the pressure by which the feeder screw pushes the raw material down and between the first roll and the second roll; and

a control unit that controls the variable-speed control motor so that the rotation of the feeder screw is decreased or increased in accordance with the values detected by the detector.

the first roll and the second roll, one of which is fixed in the direction of its radius and the other of which can contact, and retract from, the one of the first roll and the second roll in the direction of its radius;

a hydraulic cylinder that applies the pressure on the other of the first roll and the second roll if the force is exerted on the other one of the first roll and the second roll in such a way that the one of the first roll and the second roll retracts from the other one of the first roll and the second roll;

a hopper that is disposed above the first roll and the second roll;

a feeder screw disposed within the hopper, which screw pushes the raw material within the hopper down and between the first roll and the second roll by the screw being rotated;

a variable-speed control motor that rotates the feeder screw;

a detector that detects the driving current of the driving motor that is disposed at a driving unit; and

a control unit that controls the variable-speed control motor so that the rotation of the feeder screw is decreased or increased in accordance with the values detected by the detector.

the first roll and the second roll, one of which is fixed in the direction of its radius and the other of which can contact, and retract from, the one of the first roll and the second roll in the direction of its radius;

a hydraulic cylinder that applies the pressure on the other of the first roll and the second roll if the force is exerted on the other of the first roll and the second roll in such a way that the one of the first roll and the second roll retracts from the other one of the first roll and the second roll;

a hopper that is disposed above the first roll and the second roll;

a feeder screw disposed within the hopper, which screw pushes the raw material within the hopper down and between the first roll and the second roll by the screw being rotated;

a variable-speed control motor that rotates the feeder screw;

a detector that detects the power consumption of the driving motor that is disposed at a driving unit; and

a control unit that controls the variable-speed control motor so that the rotation of the feeder screw is decreased or increased in accordance with the values detected by the detector.

(link:www.briquettemachinery.com)

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)