-

This carbvonization furnace adopts a movable steel plate structure, the exhaust pipe of the furnace at the top of turn connection with the tar separator and induced draft fan, with features of a unique structure, the big effective volume, advanced carbonization technology, short carbonization cycle, high output, good environmental conservation, long life etc.

-

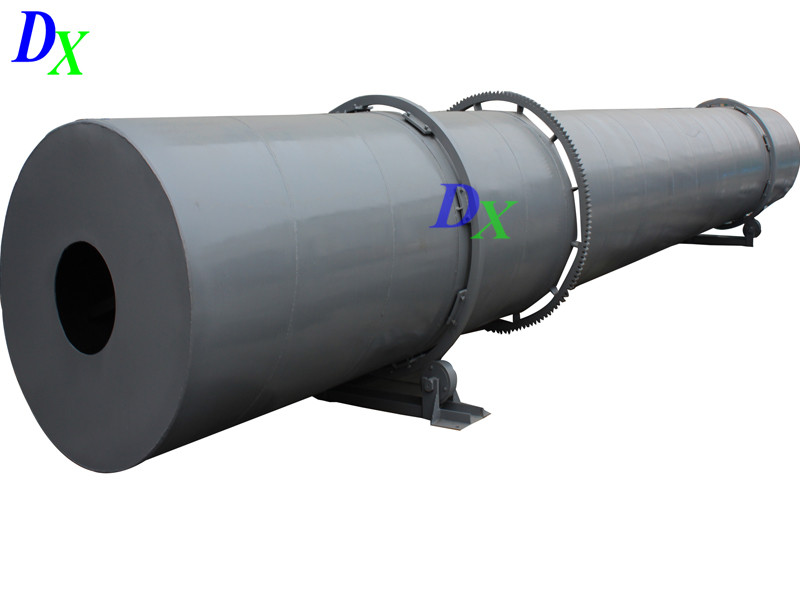

Rotary dryer, also known as rotary drum dryer, is mainly used in compound drying, also widely used in building material, metallurgy, chemical industry, cement, lime powder, coal slag, drying, etc.

-

Mesh belt dryer is a continuous penetrating flow drying equipment applied for drying pieces strip and particles state materials with good ventilation.

The drying machine is suitable for food, agriculture products and by-products, dehydrated vegetable, Chinese herbal medicine, fish products, feed and chemical industry and are suitable for drying of flaked, striped, cube and granule materials. -

A rotary kiln is a pyroprocessing device used to raise materials to a high temperature (calcination) in a continuous process. Materials produced using rotary kilns include: Cement, Lime, Refractories, Metakaolin,Titanium dioxide, Alumina, Vermiculite,Iron ore pellets.

-

Rotary Cooler can greatly improve the cooling rate, reduce labor intensity and improve production and further removal of the water and reduce fertilizer tablets temperature. At the same time it can also be used for other powder, granular material in the cooling. can greatly improve the cooling rate, reduce labor intensity and improve production and further removal of the water and reduce fertilizer tablets temperature. At the same time it can also be used for other powder, granular material in the cooling.

-

Vertical dryer is widely used in building materials, metallurgy, and chemical industry which use the hot air as thermal medium to dry the grain.

Internal is mainly composed by air ventilation and horns ventilation box, outside the box filled with grain horns, grain, hot air flow of top-down by air ventilation quarter, down through the bread into the direction of the exhaust gas layers, horns box.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)

.jpg)