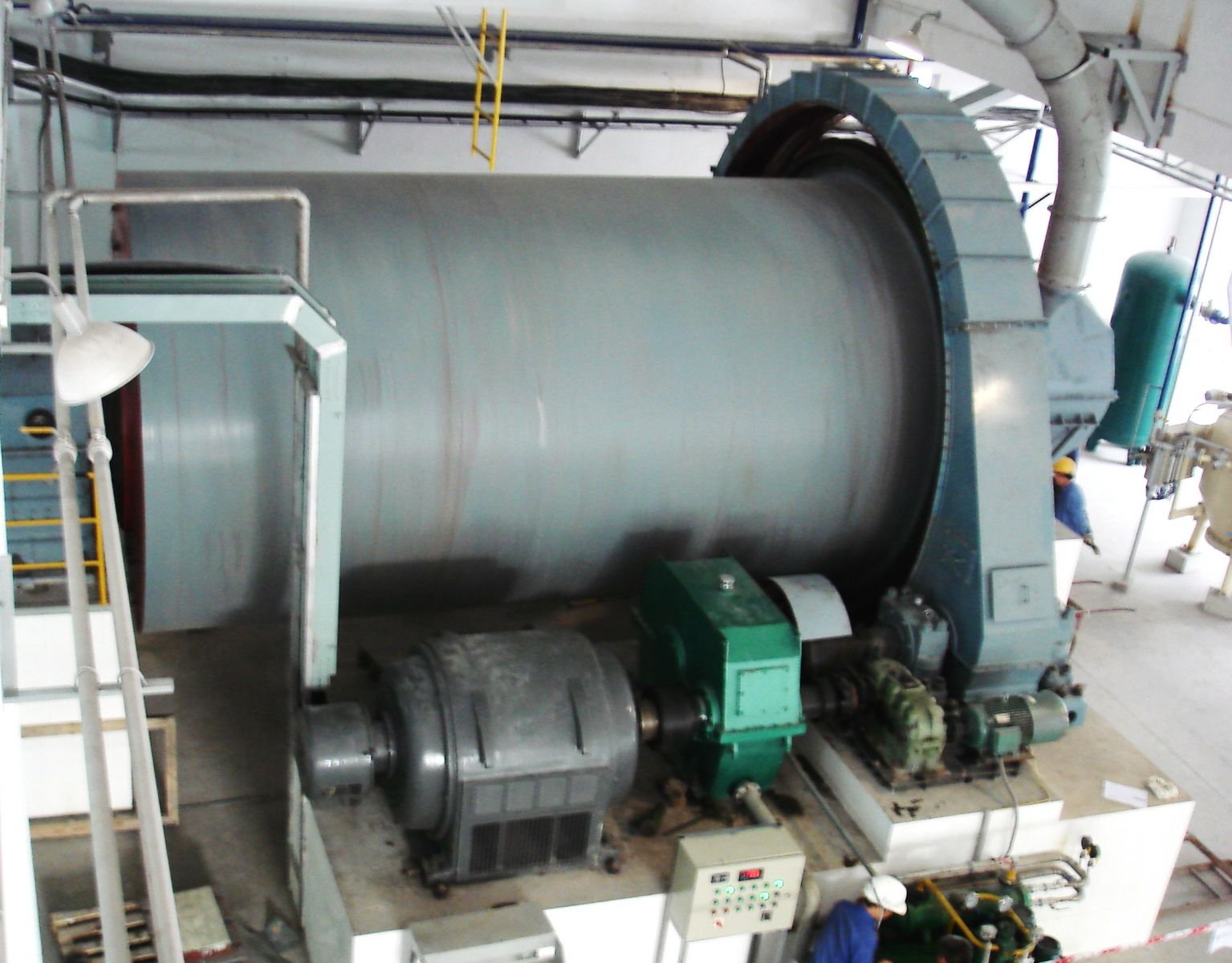

Coal Ball Mill

- Feed Size: 0-25mm

- Capacity: 0.65-28t/h

- Raw materials: coal

- Application: thermal power plants or cement plant.

Coal ball mill is one of auxiliary equipment in coal-fired power stations, and the theme equipment in coal powder equipment system. This series of ball mill is mainly used for grinding various hardness of pulverized coal. Also it applies to cement, metallurgy, chemical industry and mineral coal and raw material system powder system.

Advantages of the Coal Ball Mill:

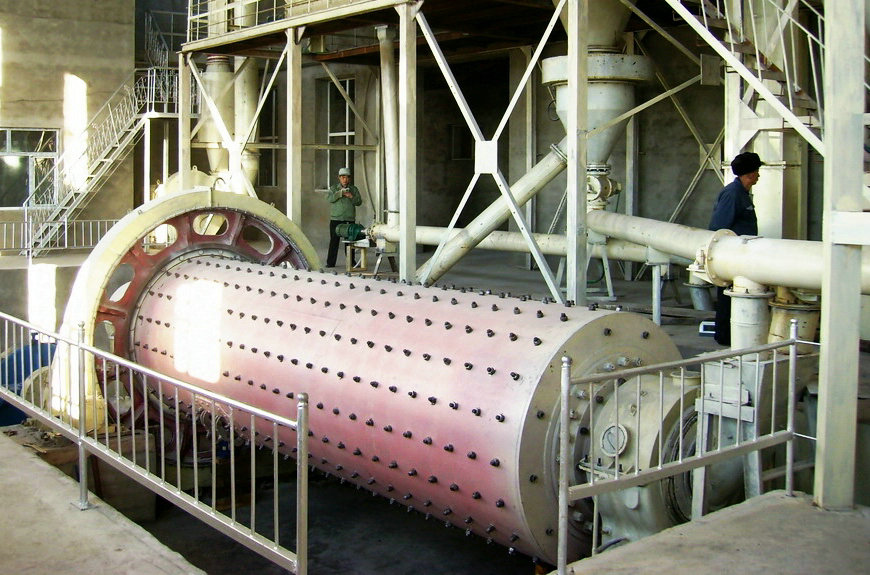

1. Coal ball mill the intrinsic grinding machine structure. Coal ball mill body and ground plank are an integral whole, so when fixing, it can be lowered on a plane surface once only.

2. Using double tiered roller axletree with centripetal spherical surface as the support of the host axletree can reduce energy cost by 30%.

3. The intrinsic grille pattern forcing evacuation is instead by overflow pattern controlling one. Coal ball mill can improve the milling of the granule and the capacity be increased by 15-20%.

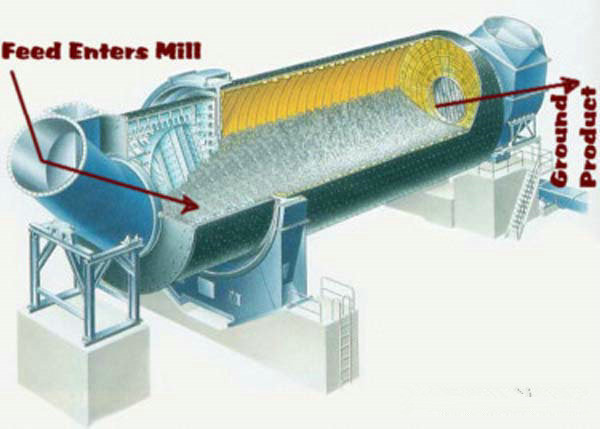

Coal Ball Mill Working Principle:

Technical Parameter of Coal Ball Mill

|

Type

|

Speed(r/min)

|

Ball Weight(t)

|

FeedingSize(mm)

|

Output size(mm)

|

Capacity(t/h)

|

Power(kw)

|

Weight(t)

|

|

Ф900×1800

|

36~38

|

1.5

|

≤20

|

0.075-0.89

|

0.65-2

|

18.5

|

4.3

|

|

Ф900×3000

|

36

|

2.7

|

≤20

|

0.075-0.89

|

1.1-3.5

|

22

|

5.3

|

|

Ф1200×2400

|

36

|

3

|

≤25

|

0.075-0.6

|

1.5-4.8

|

30

|

11.4

|

|

Ф1200×3000

|

36

|

3.5

|

≤25

|

0.074-0.4

|

1.6-5

|

37

|

12.8

|

|

Ф1200×4500

|

32.4

|

5

|

≤25

|

0.074-0.4

|

1.6-5.8

|

55

|

13.8

|

|

Ф1500×3000

|

29.7

|

7.5

|

≤25

|

0.074-0.4

|

2-5

|

75

|

16.8

|

|

Ф1500×4500

|

27

|

11

|

≤25

|

0.074-0.4

|

3-6

|

95

|

21

|

|

Ф1500×5700

|

28

|

12

|

≤25

|

0.074-0.4

|

3.5-6

|

110

|

25.8

|

|

Ф1830×3000

|

25.4

|

11

|

≤25

|

0.074-0.4

|

4-10

|

130

|

29

|

|

Ф1830×4500

|

25.4

|

15

|

≤25

|

0.074-0.4

|

4.5-12

|

155

|

35.5

|

|

Ф1830×6400

|

24.1

|

21

|

≤25

|

0.074-0.4

|

6.5-15

|

210

|

43

|

|

Ф1830×7000

|

24.1

|

23

|

≤25

|

0.074-0.4

|

7.5-17

|

210

|

43.8

|

|

Ф2100×3000

|

23.7

|

15

|

≤25

|

0.074-0.4

|

6.5-36

|

155

|

34.8

|

|

Ф2100×4500

|

23.7

|

24

|

≤25

|

0.074-0.4

|

8-43

|

245

|

38

|

|

Ф2100×7000

|

23.7

|

26

|

≤25

|

0.074-0.4

|

8-48

|

280

|

46.6

|

|

Ф2200×7000

|

21.7

|

35

|

≤25

|

0.074-0.4

|

15-28

|

380

|

51.3

|

There are some other products you may be intersted in , please click to know about the details.

Carbonization furnace Shisha charcoal briquette machinery Charcoal/coal briquette machine Briquette Machine Hydraulic Briquette Machine Pellet Briquette Machine Sawdust Briquette Machine Rotary DryerSend your message to us. We'll respond as soom as possible.

Tel:086-0371-67813791 Fax:086-0371-67813761

Tel:086-0371-67813791 Fax:086-0371-67813761

.jpg)

(※ Click this button to inquiry)

(※ Click this button to inquiry)